1.Electric BoltLock (Fail Safe) (NI-100 series) body is hot.

---Power is always on when it is locked.Power is off when the door is opened. Temperature around 50℃ of the unit is considered normal.

2.ElectricBolt Lock does not function after installation.

---Check power supply (DC12V, current 1Aand above).

---Please check if the direction of thetemplate is being installed correctly.

---Check both bolt lock and reader’s points (N.O or N.C).

3.Lock willopen when force is applied on the reader (e.g. Hitting hard or vibrating thereader).

---Please check all the connections .

---Reader's N.C. points might strikeimmediately when force is being applied on it. This eventually causes thefail-safe type of lock to open when sudden power cut occurred.

4.Insufficiencyof magnetic adhesion when magnetic lock is installed.

---Please check power supply (12V or 24V)of magnetic lock.

---Please check power voltage and current(min. 12V/1A).

---When installing magnetic lock, pleasemake sure that rubber washers are not too tight which caused the unit unable toadhere tightly with the armature.

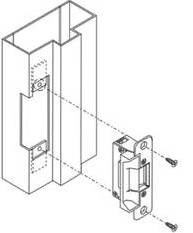

5.Types ofdoors suitable for installing strike lock.

---Suitable for all 90º wooden, aluminum, and stainlesssteel doors.

---The strike lock has to accommodate withdoor knob with latch.

---Both types of fail safe (power to lock)and fail secure (power to open) depending on users' requirement.

6.Types ofdoors suitable for installing Electric lock.

---Suitable for all 90º -180º wooden, aluminum, stainless steel, and emergency doors.

--NI-100 is fail safe type. Please installUPS to function during power cut.

---It integrates with micro-computer andpush button door open points for access control system when proximity cardentry is not applied.

---Brackets (RB-100) will need to be useddepending on the spot. Please click Accessories or her

7.Types ofdoors suitable for installing magnetic lock.

--Suitable for all 90º wooden, aluminum, stainless steel,and emergency doors.

---It is fail safe type. Please install UPSto function during power cut.

---Brackets (ZL) will need to be useddepending on the spot. Please click Accessories or here.

8.Types ofelectric locks to be installed on glass doors.

---Electric lock or electric lock whichincludes its glass holders and brackets are suitable for all 90º glass doors.

---Electric lock which includes its glassholders and brackets are suitable for all 180º glass doors.

---There are many kinds of doors availablein the market. Some doors might need brackets for easy installation. Brackets areavailable at Accessories (Lock) to fulfill your requirement.

9.Types ofelectric lock.

---There are fail-secure and fail-safetypes of electric lock. The fail-secure electric lock remains at locking statewhen the power is off. The fail-safe electric lock remains at locking statewhen the power is off and unlock when the power is off.It is not suggested toinstall fail-secure electric lock in public buildings or places as the lockwill lock when the power is off during fire accident which is hazardous to thepublic.

---Fail-safe electric lock is also named aspower-to-lock electric lock such as NI-100, NI-600/610, NI-500.

---Fail-secure electric lock is also namedas power-to-open electric lock such as NI-500, NI-400T/620/600T.

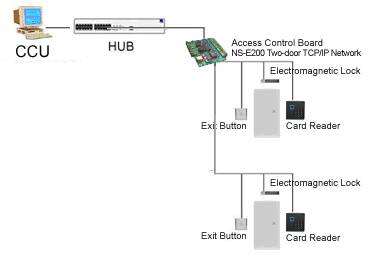

Eletromagnetic Lock and ElectricStrikes

Electromagnetic lock and electric strikeareelectrical hardware devices used to maintain the security of a door opening.Both of these devices can be activated by a range of tools, includingpasscodes, biometric readers, keycards or buzzers. When comparing magneticlocks to electric strikes, consider factors such as intended function, securityneeds, safety egress and cost to help you choose between the two.

Features

A magnetic lock, or maglock, consists of alarge magnet that is installed along the top of a door frame. A metal plate, orarmature plate, is fastened to the door so it lines up with the magnet.

When electrical power is supplied to themagnet, it creates a magnetic charge that keeps the magnet tightly pressed tothe metal plate. This keeps the door securely locked until power is removed orinterrupted.

An electric strike must be used along withsome other form of locking device, such as a lockset or exit device (panicbar). Electrical power is supplied to the strike, which holds the lock bolt inplace, keeping the door locked until the strike is activated by a buzzer,keycard or other device.

Function

With a magnetic lock, the door is alwayslocked from both sides of the opening. This makes maglocks a very secure optionfor areas that require high levels of security. Users must activate the lockwith a keycard or other device when leaving and when entering. A handle orlatchset is used to operate the door, but typically has no locking function.

Electric strikeprovide security only forthe exterior side of the door. Occupants can freely exit at anytime from insidethe building simply by turning the knob or handle, or by depressing the pad onthe exit device. From the outside, the door can only be unlocked with a keycardor other activating device, which signals the strike to release the lock bolt.

Considerations

All electrical hardware can be described aseither "fail-safe" or "fail-secure." Fail-safe hardwarestays locked when power to the hardware is cut, keeping the building secure.Fail-secure hardware unlocks once power is cut, allowing for safe egress ofoccupants.

A magnetic lock is always fail-safe, andunlocks automatically if power is cut.

Electric strike can typically be set toeither of these two options using an integral switch. All fire-rated doors mustbe equipped with fail-safe hardware for safe egress at all times.

Benefits

Because a magnetic lock is installed on theface of the door and frame, it can be installed relatively easily by mostcontractors and do-it-your owners. It is one of the most effective types ofhardware for securing both sides of a door, and provides a great door of forceto keep the door secure.

Electric strike are usually similiarlypriced to magnetic locks, making them an equally good choice for buildingmanagers on a budget. It is also easier in general to meet fire and life safetycodes with an electric strike than with a maglock. An electric strike is muchless likely to delay egress because it can be easily operated from the insideof the building.

Drawbacks

Magnetic locks can pose a potential safetyhazard in terms of slowing egress during an emergency. Because of thecomplexity of powering and installing electric strikes, they must be chosencarefully based on the type of lock they will be used with. If the wrong strikeis chosen, the lock bolt won't fit securely inside.

How Eletromagnetic Locks Works?

Eletromagnetic lock, often referred to as amag lock, consists of an electromagnet and an armature plate. The magnet ismounted inside of the door opening, which prevents tampering, while the plateis installed on the face of the door. When the magnet is connected to anelectrical source, it produces a strong magnetic attraction that holds themagnet tight to the plate, effectively locking the door. The lock is typicallypowered using either the building's electrical system or a separate batterypack. Because a mag lock can only be used with DC power, a converter unit mustbe added when relying on building power. These locks are said to be "fail-safe,"meaning that once the power goes out, the door will remain unlocked, allowingoccupants to exit safely.

Electromagnetic Theory

Maglocks are based on the science of electromagnetism. Based on the principles ofelectromagnetism, when a current is run through a loop of wire, or solenoid, amagnetic force will be produced. This magnetic force is of sufficient strengthto prevent the door from opening under a specified amount of pressure. Toincrease the strength of the magnetic force, multiple solenoids may be used, orthey may be placed around a core made of iron. The magnetic effect of thesolenoids not only produces its only force, but also amplifies the naturalmagnetism of the iron. Mag locks are rated based on the amount of force theyare able to withstand without failing. For example, a 1,200 pound Mag Lock canwithstand 1,200 pounds of force while still keeping the building secure.

One of the biggest advantages to using amag lock is that it can't be picked or tampered with like a traditional lockcylinder. No keys are used, as the lock is generally tied into an electricalsecurity system. These systems rely on one of four basic methods to operate thelock. They are often connected to a buzzer, which must be manually released bysomeone inside the building before the door will open. A mag lock may also beused with a keypad system, where occupants enter a numerical code to activatethe lock and open the door. In many commercial settings, card readers are usedwith these locks, making it easy to deactivate a card in the event an employeeis terminated or loses his/her key card. Finally, in high-security situations,the mag lock may be activated by scanners that read fingerprints, retinas, orfacial features of an occupant before they are permitted to enter.

What is an Electric Strike? HowElectric Strike works?

An electric strike is a device that'sinstalled on a door to allow access with an access control system or some othertype of remote release system. The electric strike, unlike a magnetic lockdoesn't actually secure the door. A door with an electric strike is beingsecured by the lockset or door handle. What the electric strike does is allowaccess to a secured door without the need for a key to unlock the lockset.

If you look at a normal door, you'll seethree major parts that keep it secure. The first part is the lockset. Thelockset consists of several parts but the 2 major parts are the handle and thelatch. The handle is the part that you use to open a door. The latch is thepiece that sticks out the side of the door. This is the piece that actuallykeeps the door locked and retracts whenever the handle is turned. The thirdpart is the strike (or strike plate or door strike). What the strike does isprovide an hole for the latch to rest in.

The strike looks like a metal plate with ahole in it. When the latch falls inside of the hole, it keeps the door fromopening. What the electric strike does is replace this strike plate. When theelectric strike is used, the side of the strike is cut out and has a hingedpiece of metal. The piece of metal swings whenever the release system isactivated. This allows you to open the door without unlocking the handle. Sobasically the electric strike has the same hole as the strike plate except thatthe electric strike hinges on the side to allow the latch to move out and allowthe door to open.

There are several advantages to usingelectric strikeover other types of locks. However . . .

Not all doors can use door strikes. Somedoors that do not have locksets cannot use a electric door strike since alockset is required.

Locksets may need to be replaced to use aelectric door strike. There are many different types of locksets with manydifferent functions. The correct function for an electric strike would be onethat stays locked from the outside (can be momentarily unlocked with a key butnot permanently) and has no type of lock/unlock button on the inside. Thisfunction is called a "store room function". Other types such as locksthat have a lock/unlock button on the inside would defeat the purpose of thestrike.

Permanent damage is done to door frame. Inorder to install a door strike, part of the door frame must be cut out. This isnot a problem unless you want to move the strike to another door. That wouldleave a large hole in the strike. Some manufacturers sell filler plates tocover up the hole but most of the time, the strike would just be left in thedoor and another would be purchased for another door.

So should you use an electric strike foryour access control system? Well, it all depends. There are many differenttypes of electronic locks and each lock has it's advantages and disadvantages.If you want a higher security door; one where an access card and not a key canopen... a magnetic lock may be the ticket.Nordson has a variety of options foryou.

How electric lock works?

Magnetic lock is a locking device thatconsists of an electromagnet and an armature plate. By attaching theelectromagnet to the door frame and the armature plate to the door, a currentpassing through the electromagnet attracts the armature plate, holding the doorshut. Unlike an electric strike a magnetic lock has no interconnecting partsand is therefore not suitable for high security applications because it ispossible to bypass the lock by disrupting the power supply. Nevertheless, thestrength of today's magnetic locks compares well with that of conventional doorlocks and they cost less than conventional light bulbs to operate. Powersupplies incorporating a trickle-charged lead-acid battery pack can be used toretain security for short-term power outages.

The principle behind an electromagneticlock is the use of electromagnetism to lock a door when energized. The holdingforce should be collinear with the load, and the lock and armature plate shouldbe face-to-face to achieve optimal operation.

The magnetic lock relies upon some of thebasic concepts of electromagnetism. Essentially it consists of an electromagnetattracting a conductor with a force large enough to prevent the door from beingopened. In a more detailed examination, the device makes use of the fact that acurrent through one or more loops of wire solenoid produces a magnetic field.This works in free space, but if the solenoid is wrapped around a ferromagneticcore such as soft iron the effect of the field is greatly amplified. This isbecause the internal magnetic domains of the material align with each other togreatly enhance the magnetic flux density.

Magnetic locks possess a number ofadvantages over conventional locks and electric strikes. For example, theirdurability and quick operation can make them valuable in a high-traffic officeenvironment where electronic authentication is necessary.

Advantages

- Easy to install: Magnetic locks are generallyeasier to install than other locks since there are no

- Quick to operate: Magnetic locks unlockinstantly when the power is cut, allowing for quick release in comparison toother locks.

- Sturdy: Magnetic locks may also sufferless damage from multiple blows than do conventional locks. If a magnetic lockis forced open with a crowbar, it will often do little or no damage to the dooror lock.

- Requires continuous power: To remainlocked, the magnetic lock requires a constant power source. The power drain ofthe lock is typically around 3 watts, far less than that of a conventionallightbulb (around 60 watts), but it may cause security concerns as the devicewill become unlocked if the power source is disrupted. By comparison, electric strikecanbe designed to remain locked should the power source be disrupted.Nevertheless, this behaviour may actually be preferable in terms of firesafety.

The magnetic lock is suitable for bothin-swing and out-swing doors. Brackets (L bracket, LZ bracket, U bracket) areused to adjust the space between the door and lock. The magnetic lock shouldalways be installed on the inside (secure side) of the door. Most installationsare surface mounted. For safety, magnetic lock, cables, and wires should beinserted in the door or be a flush mount. Installation is as simple asinstalling the header of the door frame for out-swinging doors or using aZ-bracket for in-swinging doors. It is important to make sure the armatureplate and the electromagnet align as closely as possible to ensure efficientoperation. Magnetic locks are almost always part of a complete electronicsecurity system. Such a system may simply consist of an attached keycard readeror may be more complex, involving connection to a central computer that monitorsthe building's security. Whatever the choice of locking system, fire safety isan important consideration.

Other variations and improvements on theelectromagnetic locks have been developed. The most remarkable is the shearlock, where the armature does not directly pull off the face, but the load isinstead in shear, like a mechanical stop. The shear magnetic lock allows a doorto swing in both directions, as opposed to the original (and now ubiquitous)direct pull type, which normally works either in an in-swing or out-swingconfiguration.

An improved 'shear' electromagnetic lockwas patented on May 2, 1989, by Arthur, Richard and David Geringer of SecurityDoor Controls, an access control hardware manufacturing firm. (Maglocks.comcarries and supports the full product offering of SDC Security) The deviceoutlined in their designs was the same in principle as the modern magnetic lockconsisting of an electromagnet and an armature plate. The patent did not makeany reference to the manufacturing methods of the electromagnet and detailedseveral variations on the design, including one that used a spring-loadedarmature plate to bring the armature plate closer to the electromagnet. Thepatent expired on May 2, 2009.

A magnetic lock has a metal plate surroundedby a coil of wire that can be magnetized. The number of coils determines theholding force which characterizes the lock:

- Micro Size: 100-300 Lbs (1,300 N) holdingforce.

- Mini Size: 600 Lbs2,700 N) holding force

- Midi Size: 800 Lbs(3,600 N) holding force

- Standard Size: 1,200 Lbs (5,300 N)holding force.

The standard size electromagnetic lock isused as a gate lock.

Electrical Requirements

The power for an electromagnet lock is DC(Direct Current), around 6 W. The current is around 0.5 A when the power is 12V DC. Generally, the specification of the electromagnet locks is dual voltages12/24 V DC. Single voltage output can be required for 12 V DC or 24 V DCapplications. The figure presents the relationship between voltage and holdingforce. When the current is fixed, voltage is proportional to power consumption.

Application modes

For safety purposes, electric locks can bedesigned to operate in one of two modes:

Fail Safe – to protect people: The lock is released if power cuts off.

Fail Secure – to protect property: The lock remains closed if power cuts off.

An electromagnet lock is normally used inFail-Safe situations, so it must satisfy applicable fire regulations so as tobe safe in emergency situations.

Add: Room 417, Sun\'gang Building, No. 23, Baogang

Add: Room 417, Sun\'gang Building, No. 23, Baogang Tel: +86-755-8637 7711

Tel: +86-755-8637 7711  Fax: +86-755-8276 2979

Fax: +86-755-8276 2979  Website:

Website: